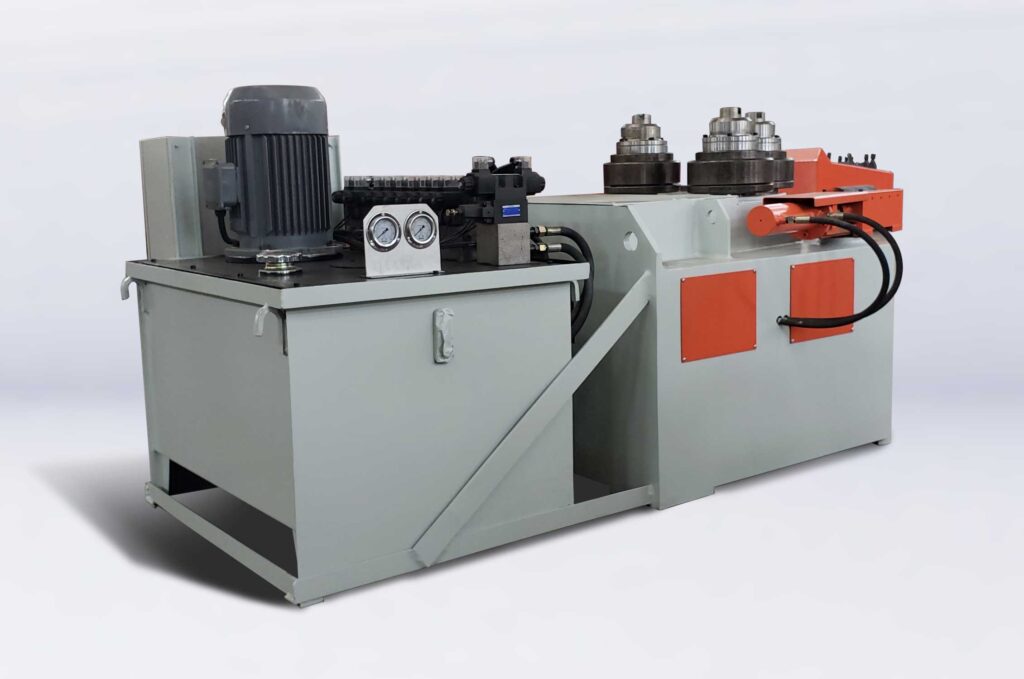

The PBC-100, PBC-120, PBC-140, and PBC-200 profile bending machines, also known as “Angle Rollers” because they are commonly used in workshops for bending angle profiles. These compact machines cover bending needs from light to medium-duty processing and are especially suited for rolling angle steel, flat steel, and other small structural components, making them ideal for startups and small to medium-sized processing workshops. The entire series comes equipped with a versatile Universal Tooling Set, which can be quickly adjusted to accommodate different profile specifications, significantly improving machine utilization while reducing investment costs for users.

Names such as Angle Rolls, Angle Iron Roller, and Section Bending Machine

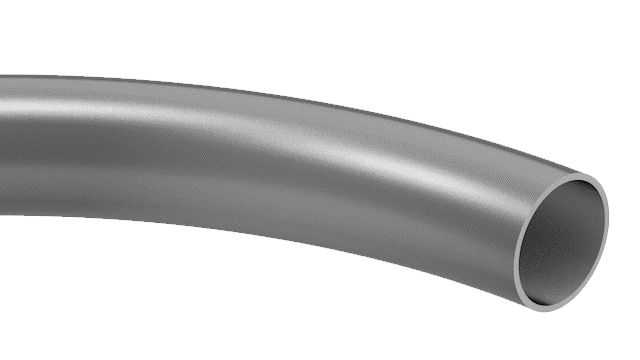

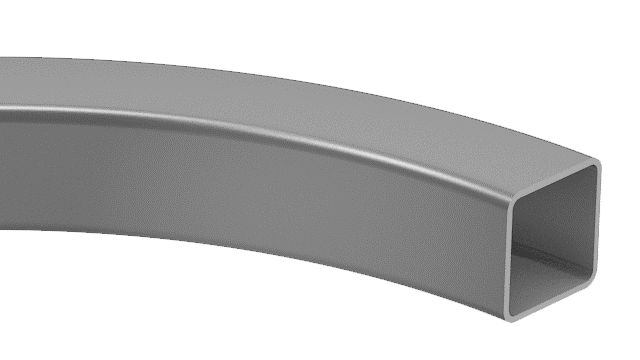

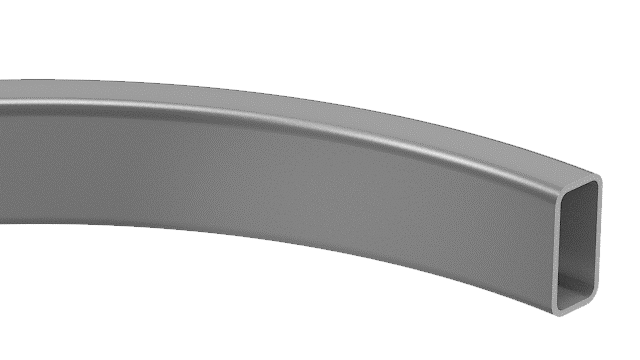

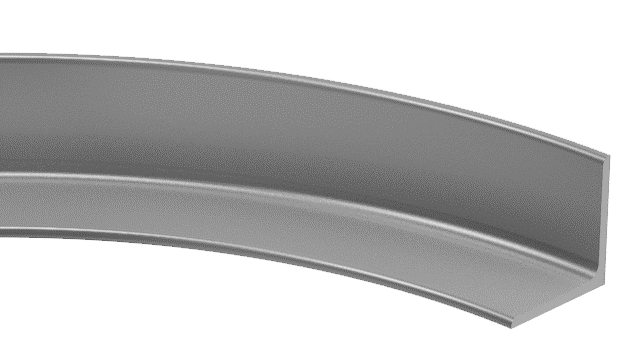

In regions like North America, these machines are often referred to as “Angle Rollers” or “Angle Iron Rollers” due to their exceptional performance in angle steel processing. However, from a technical standpoint, a more accurate term would be “Section Bending Machine,” as they are capable of bending not only angle steel but also flat steel, round pipes, square pipes, and other profiles. This naming difference reflects the emphasis placed on the equipment’s capabilities in different markets, but regardless of the name, the core function remains precision rolling of various metal profiles.

Specifically, for Leg-In angle steel processing, which tends to cause twisting issues, the PBC series is equipped with a specialized Anti-Twist Correction System, including Tri-Directional Lateral Guides and Cam Rollers, effectively solving this industry challenge.

Basic Parameters

| Item | PBC 100 | PBC 120 | PBC 140 | PBC 200 |

|---|---|---|---|---|

| Section Modulus (cm³) | 3-10 | 10-20 | 16-45 | 45-75 |

| Bending Speed (m/min) | 4.5 | 4.5 | 4.5 | 4.5 |

| Guide Rolls Moving Speed (m/min) | 1.6 | 1.6 | 1.6 | 1.6 |

| Upper Shaft Diameter (mm) | 80 | 95 | 120 | 140 |

| Lower Shaft Diameter (mm) | 70 | 85 | 110 | 130 |

| Bending Roller Diameter (mm) | 145 | 256 | 330 | 385 |

| Hydraulic Motor Power (kW) | 3.0 | 5.5 | 6.0 | 11.0 |

| Weight (kg) | 1500 | 3600 | 4000 | 4500 |

| Diameter (mm) | 1600×1600×1350 | 2200×1800×1800 mm | 2200×2000×1800 mm | |

| – |  |  |  |

Capacity Table for Bent Profiles

| Profile & Bending Method | PBC-100 | PBC-120 | PBC-140 | PBC-200 | Mold & Tool |

|---|---|---|---|---|---|

| 80×15 Φ500 | 80×18 Φ800 | 100×25 Φ900 | 120×25 Φ1000 | ○ |

| 125×25 Φ500 | 180×20 Φ500 | 200×35 Φ900 | 250×30 Φ1000 | ○● |

| 40×40 Φ500 | 50×50 Φ500 | 60×60 Φ600 | 70×70 Φ700 | ○ |

| Φ50 Φ500 | Φ60 Φ600 | Φ70 Φ700 | Φ80 Φ800 | ● |

| Φ60 Φ500 | Φ76 Φ700 | Φ102 Φ1100 | Φ142 Φ1800 | ● |

| 50×50×6 Φ800 | 65×65×6 Φ1000 | 90×90×6 Φ1500 | 100×100×6.5 Φ1500 | ○● |

| H: max.25 W: max.55 Φ800 | H: max.40 W: max.70 Φ1000 | H: max.50 W: max.100 Φ1500 | H: max.60 W: max.120 Φ1500 | ○● |

| H: max.100 W: max.50 Φ800 | H: max.100 W: max.60 Φ1000 | H: max.120 W: max.90 Φ1500 | H: max.120 W: max.100 Φ1500 | ○● |

| 60×60×7 Φ750 | 80×80×10 Φ1000 | 100×100×10 Φ1000 | 100×100×12 Φ1250 | ○△ |

| 60×60×8 Φ700 | 80×80×10 Φ800 | 100×100×12 Φ1200 mm | 120×120×12 Φ1250 | ○△ |

| 60×60×7 Φ750 | 80×80×9 Φ1300 | 100×100×12 Φ1500 | 100×100×12 Φ1500 | ○△ |

| 60×60×8 Φ500 | 80×80×10 Φ700 | 100×100×12 Φ800 | 120×120×13 Φ1250 | ○△ |

| 60×60×8 Φ640 | 100×100×12 Φ1000 | 120×120×13 Φ1200 | 140×140×15 Φ1250 | ○△ |

| UPN 120 Φ700 | UPN 140 Φ800 | UPN 160 Φ1000 | UPN 200 Φ1000 | ○● |

| UPN 120 Φ600 | UPN 140 Φ600 | UPN 160 Φ800 | UPN 200 Φ900 | ○● |

| Max. Section Mudulus: 6-15 cm³ | UPN 65×42 Φ4000 | UPN 80×45 Φ5000 | UPN 100×50 Φ8000 | ○●▲ |

| IPE 100 Φ600 mm HEA Max. Section Mudulus: 6-15 cm³ | IPE 140 Φ600 mm HEA Max. Section Mudulus: 16-25 cm³ – | IPE 160 HEA 120 HEB 100 Φ800 | IPE 200 HEA 140 HEB 120 Φ900 | ○● |

| HEA IPE Max. Section Mudulus: 6-15 cm³ | IPE 80 Φ1200 HEA Max. Section Mudulus: 16-25 cm³ | IPE 100 Φ1500 HEA Max. Section Mudulus: 25-45 cm³ | IPE 120 Φ2500 HEA Max. Section Mudulus: 45-75 cm³ | ○●▲ |

○: Standard Roller

●: Custom Roller

△:Standard Tool

▲: Custom Tool

○●: Standard Roller or Custom Roller