Profile Bending Machine

Precision Redefined: Perfect CNC Profile Rolling for Every Curve

What is

Profile Bending Machine?

For cold-bended structural sections (aluminum or steel), common technologies include Profile Rolling Machines, Stretch Forming Presses, Craft Formers, and Freeform Benders.

(Small Note: In industry parlance, “Profile Bending Machine” typically refers to the Profile Rolling Machine.)

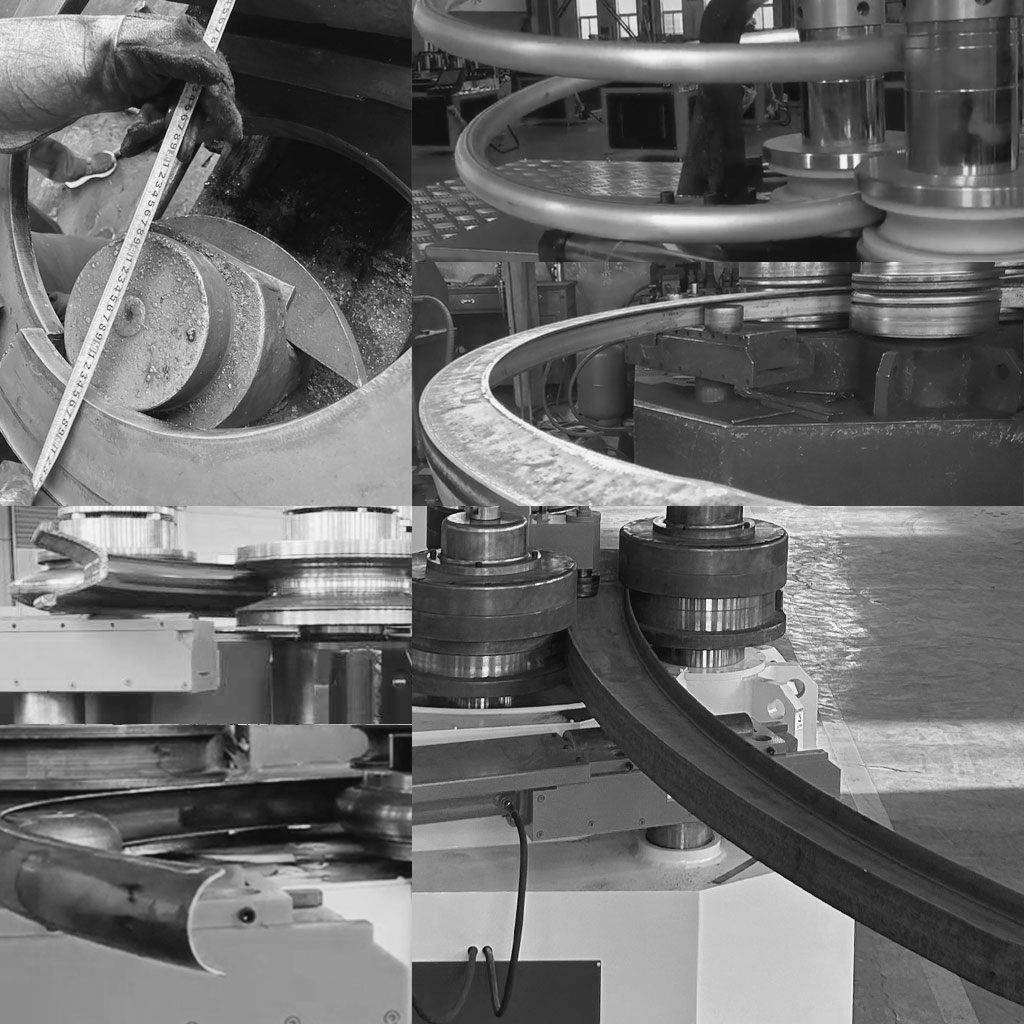

The Profile Rolling Machine is a precision-engineered cold-rolling solution designed to shape a wide array of metal sections. Featuring robust rollers capable of processing aluminum, steel, and advanced alloys, it delivers consistent circular, semi-circular, or complex arched geometries with industrial-grade accuracy.

30+ years. BIT provides a CNC Profile Bending Machine for big mass-producing profile curved parts. We adopt high accuracy servo hydraulics and motors for profile bending machines.

The Profile Bending Machine is named as Section Bending Machine, Section Rolling Machine, Profile Rolling Machine, Angle Roller, Angle Iron Roller and Section Bender.

Types of

Profile Bending Machine

Depending on the application, our PBA (View Capacity Table)and PBC (View Capacity Table). series vary in construction and precision. While the standard machine is a 3-roller, we also offer customized 4-roller solutions to meet your specific needs.

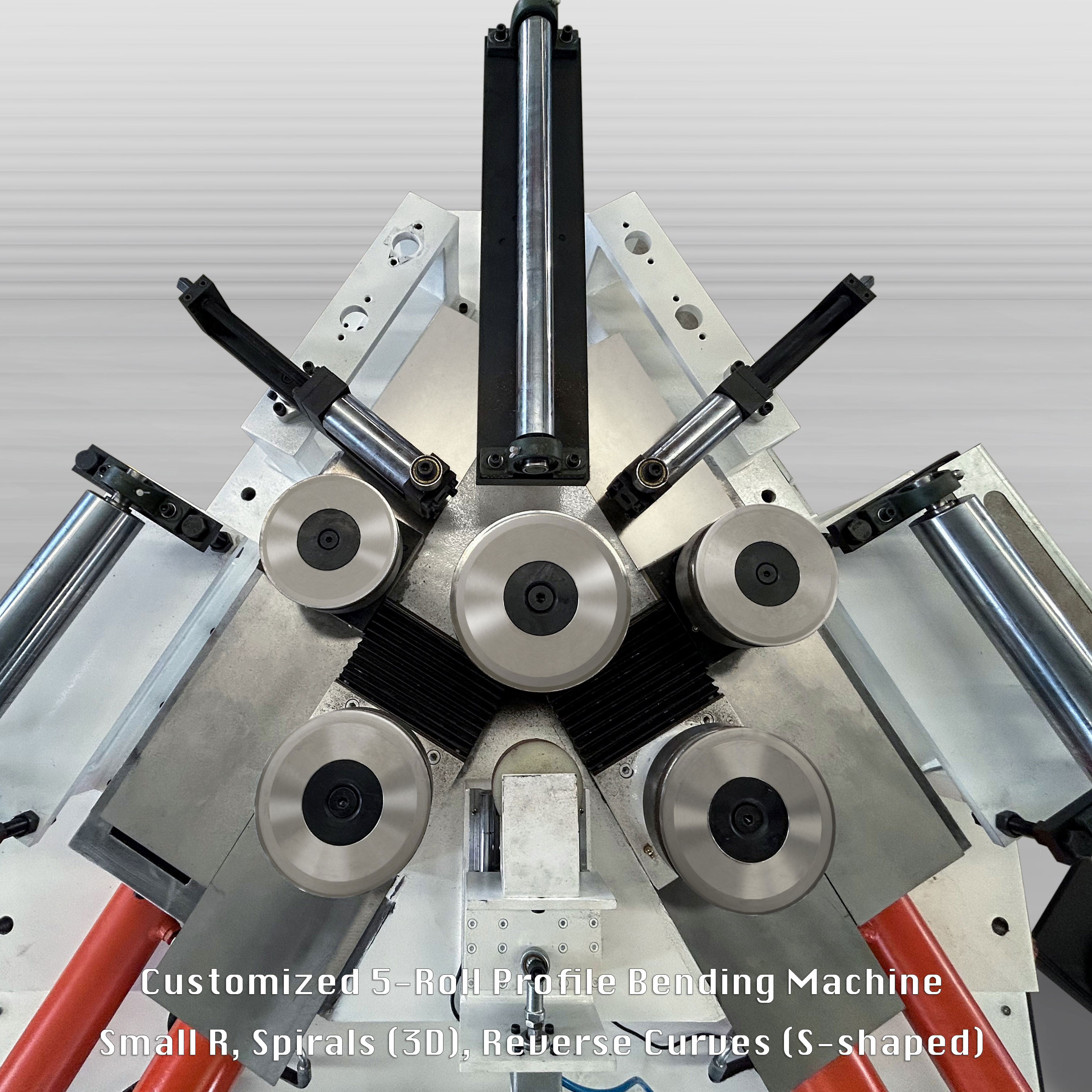

Roller Configuration: 3-Rolls: The industry standard for versatility and reliability across most applications. 4-Rolls: Designed for enhanced precision with superior material clamping and significantly reduced flat ends. 5-Rolls: Less common, engineered for specific high-precision complex profiles.

Control System: Manual Control: Direct operator interface, ideal for simple tasks or small-scale fabrication. PLC & CNC Control: A fully automated, high-precision system designed for complex geometries, multi-radius bending, and spiral shapes.

Driving System: Electric Motor Drive: Light to medium-duty tasks. Hydraulic Drive: Delivers max. power and torque for heavy-duty structural steel and large-scale sections. Servo Motor Drive: Provides high-speed, high-precision performance with superior energy efficiency—ideal for aluminum extrusions. Servo-Hydraulic Drive: Combining the massive power of hydraulics with the pinpoint precision and energy efficiency of servo control.

Bending Geometry: Pyramidal: A classic design where the top roll moves vertically; ideal for standard symmetrical bending. Single Pinch: Features one adjustable side roll, allowing for better pre-bending of one end of the profile. Double Pinch: Both side rolls move independently, allowing for the highest precision and the ability to pre-bend both ends in a single pass.

Machine Orientation: Vertical Type: A compact, space-saving design. Horizontal Type: The preferred orientation for extra-large, heavy, or ultra-long profiles to prevent gravitational distortion during the bending process.

Bending Accuracy

The PB Series Profile Bending Machine provides perfect profile bending and the highest bending accuracy and is used in various industries and fields that require the highest production quality.

Precision Control: Laser Compensation: Integrated system for real-time radius measurement and automatic spring-back coefficient storage. Repeat Position Accuracy: 0.01mm (PBA) / 0.02mm (PBC), guaranteeing identical output for high-volume production batches.

Surface Integrity: Speed Micro-Adjustment: 0.1 mm/s precision feed to eliminate impact marks and surface scuffing. Electronic Sync: All-axis differential control with < 0.1% sliding friction, preventing Galling on polished stainless or decorative aluminum.

CNC Tracking: Eliminates roller slippage for pinpoint arc length and multi-radius transition accuracy.

BIT Tooling: High-Speed Protection: Specialized tooling design that maintains surface integrity at maximum bending speeds. Industrial Scale: Ensures “zero-damage” surface quality on large-scale workpieces without compromising throughput.

Uses of

Profile Bending Machine

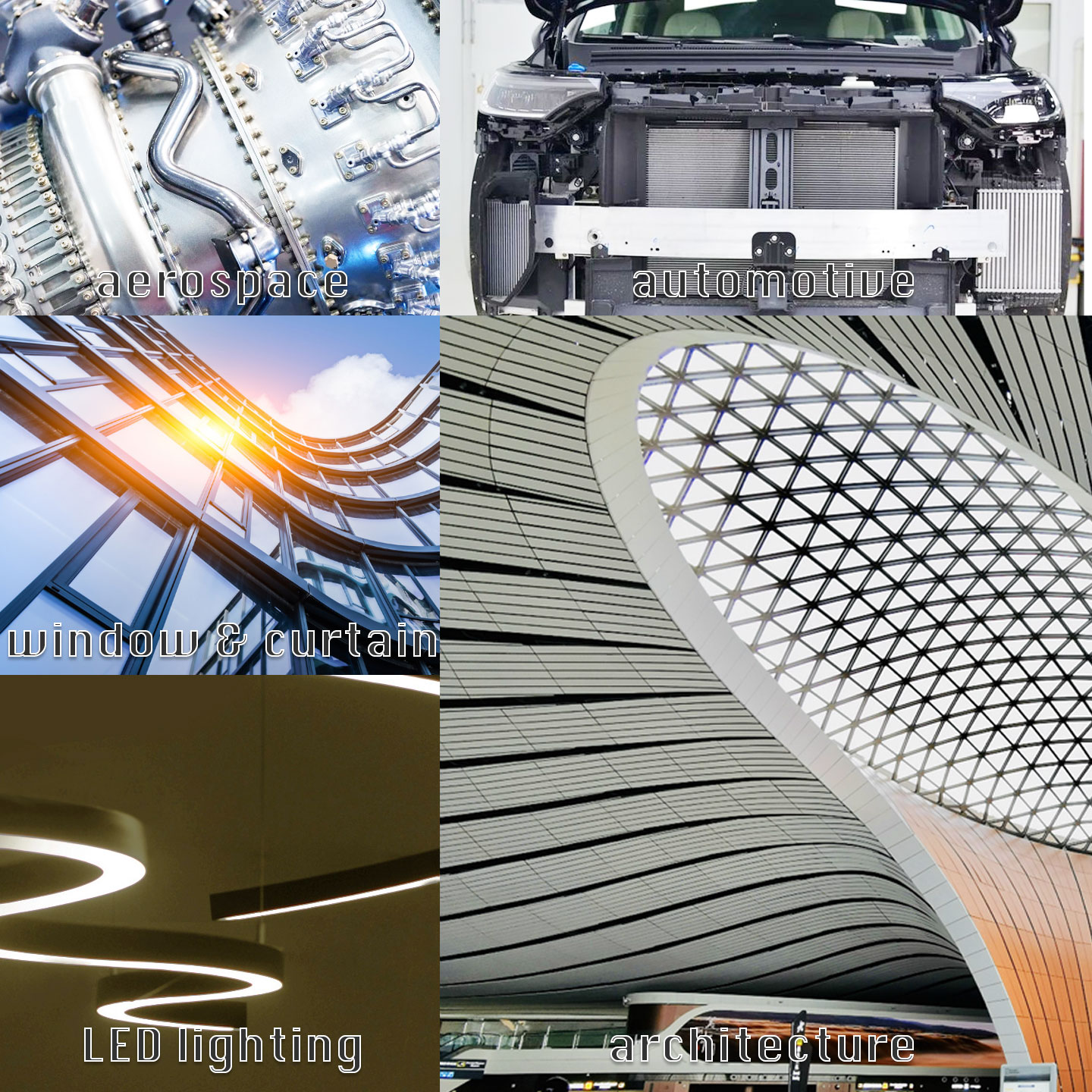

Profile bending machines offer versatile cold-forming solutions for a wide range of materials—from aluminum and copper extrusions to hot-rolled structural steel sections—producing perfectly curved workpieces for diverse industries:

The PBA Series is the ideal choice for high-precision forming of aluminum extrusions, engineered specifically for processes demanding ultimate accuracy; meanwhile, the PBC Series excels in bending a wide range of heavy-duty structural metal profiles, easily handling angle iron, flat bars, pipes (including spiral tubes), and various large-scale structural beams, such as T-beams, I-beams (IPE), H-beams (HEA, HEB, ISMB), and U-channels.

Architecture & Curtain Walls: Curved aluminum windows and doors, circular curtain wall frames, skylight structures, arched sunrooms, curved beams, and architectural facades.

Transportation & Automotive: High-speed train body components, arched roof beams, interior structural parts, crash beams (impact bars), roof frames, luggage racks, and door reinforcement sections.

Heavy Industry & Machinery: Mining conveyor components, mechanical equipment frames, nuclear power structural supports, oil and gas pipelines, large-scale structural steel sections, and industrial piping.

Furniture, Commercial & Decor: Curved railings, display racks, decorative metal elements, lighting fixtures, artistic sculptures, and furniture frames.

Sports & Public Facilities: Arched beams for stadiums and arenas, public seating structures, and landscape architectural elements.

Shipbuilding & Marine: Hull framing, safety handrails, and deck structural components.

Aerospace: Fuselage frames, wing ribs, cabin door structures, and high-precision components with strict springback control requirements.

What are the

Construction & Features?

The profile bending machine integrates a rigid frame, precision spindle system, modular rolls, electro-hydraulic or servo drives, and CNC control.

The high-precision PB Series CNC profile bending machine is controlled by a motion control system and driven by either servo motors (aluminum extrusion workpieces) or a servo-hydraulic system (heavy-duty bending), enabling accurate bending of both standard and complex curves that excels in both high-precision aluminum forming and heavy-duty structural steel processing.

Frame: Closed-loop frame design enhances bending and torsional rigidity for stable performance under demanding conditions.

Spindle System: Spindles are made from through-hardened 42CrMo alloy steel and precision-ground. The rigid support structure withstands axial and radial loads during bending.

Modular Tooling: Rollers (HRC 55–60) use a segmented modular design, allowing flexible configuration for various profile cross-sections.

Drive System: X and Y axes use electro-hydraulic proportional or fully electric servo drives, depending on configuration. The Z-axis enables multi-axis interpolation for 3D curve forming.

NC Intelligence: Based on PLC or CNC architecture, supporting multi-axis synchronization and parametric programming. Includes material database and springback compensation, with optional radius measurement for real-time correction.

Leveraging 30 years of expertise, this machine combines intuitive CNC control with high-torque multi-axis drive to achieve ultra-tight radii and complex 3D shapes without cracks or deformation.

How it Works?

When the material properties permit, the PB series profile bending machine’s high torque enables single-pass bending, eliminating multiple forming steps and significantly improving efficiency.

The PB Profile Bending Machine utilizes CNC automation to achieve simple three-point bending of complex shapes, enabling the most cost-effective cold roll-bending with high precision and efficiency: Easy Operation, Low Costs, and Reduced Assembly.

Pre-Bending Preparation: The profile is positioned in the rolling area. DXF/STEP files are imported via the CNC system (manual parameter input is also available). The system generates the bending path and initializes process parameters.

Initial Positioning: Displacement sensors calibrate the initial roller position to ensure alignment with the theoretical model. Clamping and Pre-Bending: The upper or side roller feeds radially to clamp the profile. The servo system provides stepless pressure or flow control to start pre-bending.

Incremental Rolling: Three rollers rotate synchronously, driving the profile by friction. The CNC system adjusts roller feed after each pass, gradually reducing the bending radius. Single-pass forming is possible depending on material and section properties.

Measurement and Compensation: Laser or displacement sensors measure actual dimensions and curvature. The system calculates springback and performs final correction to achieve the target shape.

Retraction and Reset: The rollers retract to the home (initial) position, the clamping force is released, and the machine resets, preparing for the next rolling cycle.

Customer

Partnerships That Grow

In China, we maintain long-term and stable win-win partnerships with several bending factories, growing together. As our partners’ businesses expand, they have successively purchased multiple machines, ranging from light to heavy-duty profile bending machines.

- Driven by customer collaboration, practical innovations create perfect profile bending.

- Same model, same power, greater bending capacity (compared to competitors).

- Complete tool configuration ensures no deformation of the section (e.g., angle bending device).

- Servo motor drive for aluminum bending ensures consistent bending workpieces, consistent line speed and high torque. (China patent protected, PBA).

- Variable Geometry Rolls: Minimizes unbend ends and achieves precise bends with small radii. (China patent protected, PBA).

- 30+ Years of Bend Tool Design: offering perfect solutions, No Section Deformation, No Surface Wrinkles, and No Cracking.

About US

Profile bending machines for aluminum and carbon steel are among our key products. Over 1,000 world-renowned companies, including Sany, Zoomlion, Fuyao, and BYD, have chosen our solutions.

Borisbang Industrial Technology (BIT) specializes in profile bending machines and other metal cold bending machinery.

With a highly trained technical team and a diverse range of quality machines, including profile bending machines, plate rolling machines, fluid cell presses, and 3D freeform tube benders, we deliver excellence. Our commitment to on-time deliveries and customer satisfaction has earned us a loyal global client base.