Bending angle profile: Leg Out & Leg In often lead to section twisting. The PBC series angle bending machines correct this by adjusting the bending guide rollers and the straighteners—small guide rollers designed specifically for angle bending.

Angle iron is an asymmetrical profile that tends to twist during bending. Proper setup of guide rollers and supporting components is critical to ensure accurate results, minimize deformation, and produce a consistent curve. This article outlines two key methods for bending angle iron: Leg Out and Leg In.

Bending Angle Iron – Leg Out

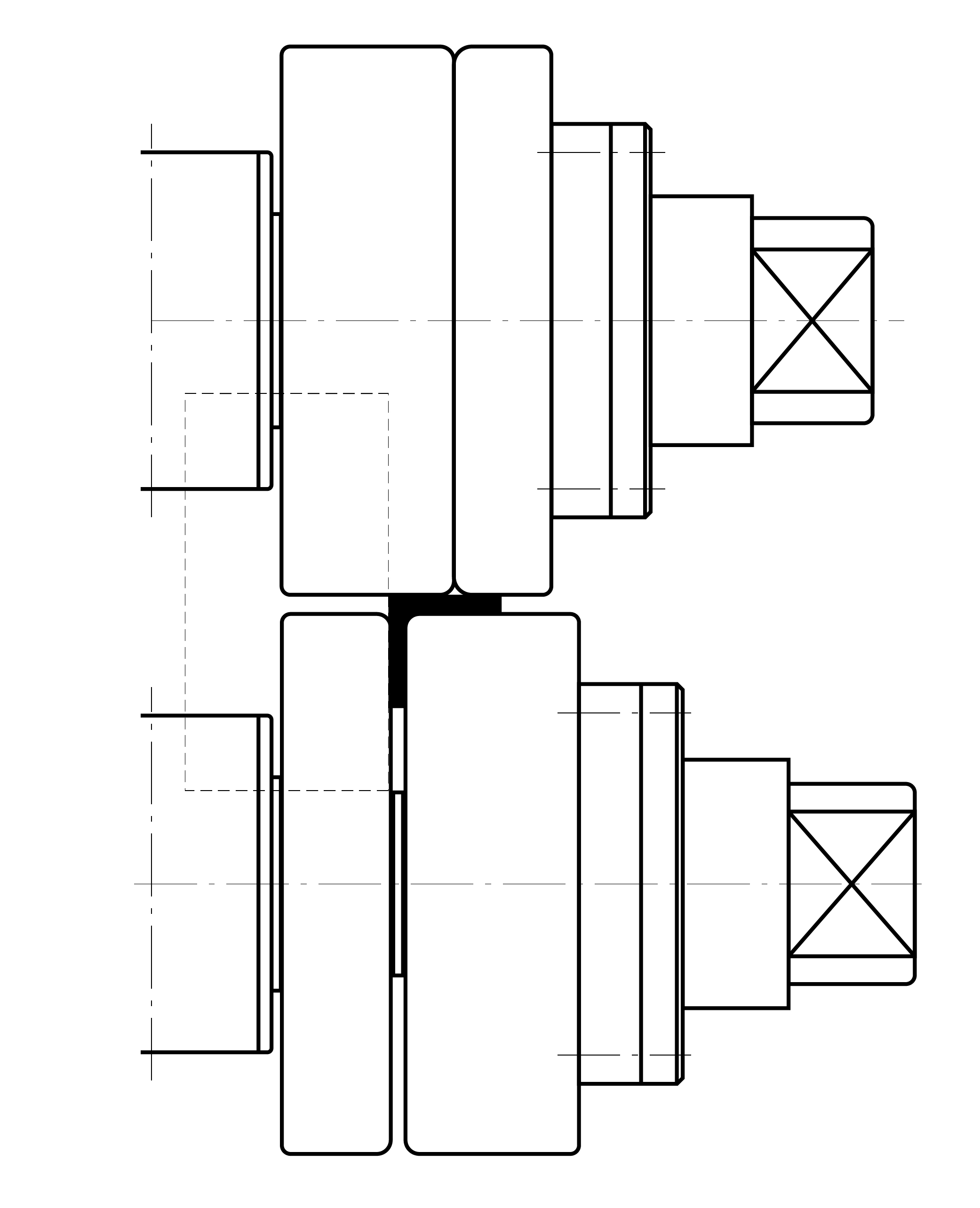

In the leg out configuration, the vertical leg of the angle iron faces outward from the center of the machine. This is the more commonly used method and allows effective use of 3D guide rollers and small guide rollers to prevent twisting.

Guide Roller Setup:

Keep the left guide roller aligned with the profile for light support. Increase pressure on the right guide roller to counteract distortion during bending.

If the profile struggles to pass the right guide roller, temporarily move it closer to the machine, let the profile pass through, then use a wrench to manually readjust the roller.

- Additional Anti-Twist Measures (for PBC machines):

- Install larger-diameter flanges on the lower rollers to provide lateral support.

- Gradually adjust the 3D guide rollers during bending to prevent outward twist.

- When performing asymmetric pre-bending and symmetric rolling, loosen the friction clutch to enhance stability and rolling accuracy.

This method is effective for maintaining control and reducing error in most bending applications involving asymmetrical sections.

Bending Angle Iron – Leg In

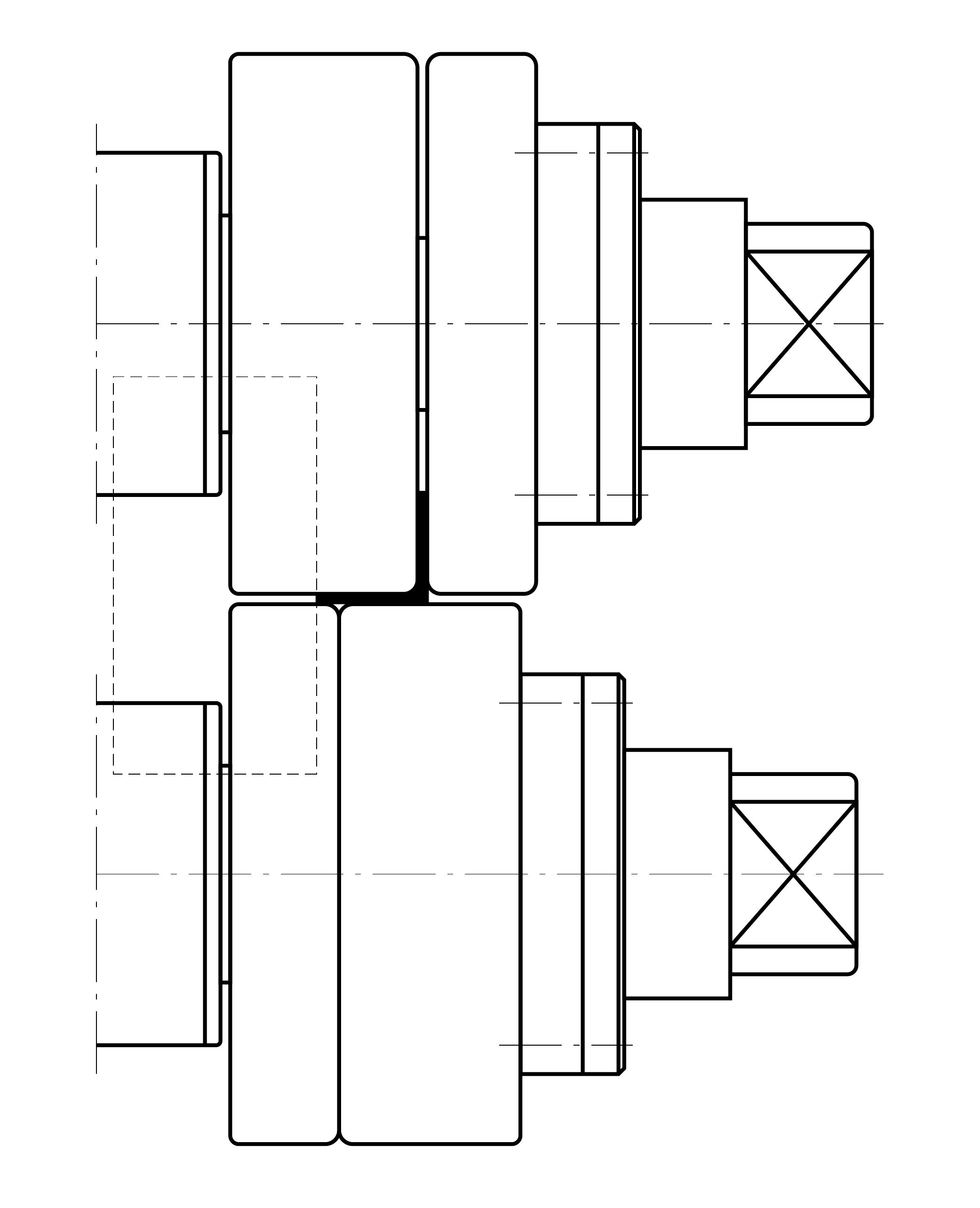

The leg in configuration—where the vertical leg faces inward toward the machine’s top roll—is more complex and requires precise handling.

Initial Setup:

Position one leg of the profile against the top central roll and the other toward the frame. Twisting is common at the beginning. To correct this:

- Lower one side guide roller.

- Advance the opposite side roller until the profile straightens.

Bending and Roller Adjustment Process

On PBC machines, both 3D guide rollers and small guide rollers are used to apply corrective forces. Follow this step-by-step approach:

- Begin bending with the 3D guide roller guiding the flange.

- Feed the profile until it reaches the small guide roller and adjust to maintain alignment.

- Avoid over-adjusting the small roller, as it may induce inward twisting.

- Once the profile reaches the midpoint of the 3D guide roller, stop and reverse-roll from the other end.

- Repeat the process to ensure a consistent curve and complete the ring without distortion.

This method demands careful control but produces high-quality results for challenging applications.