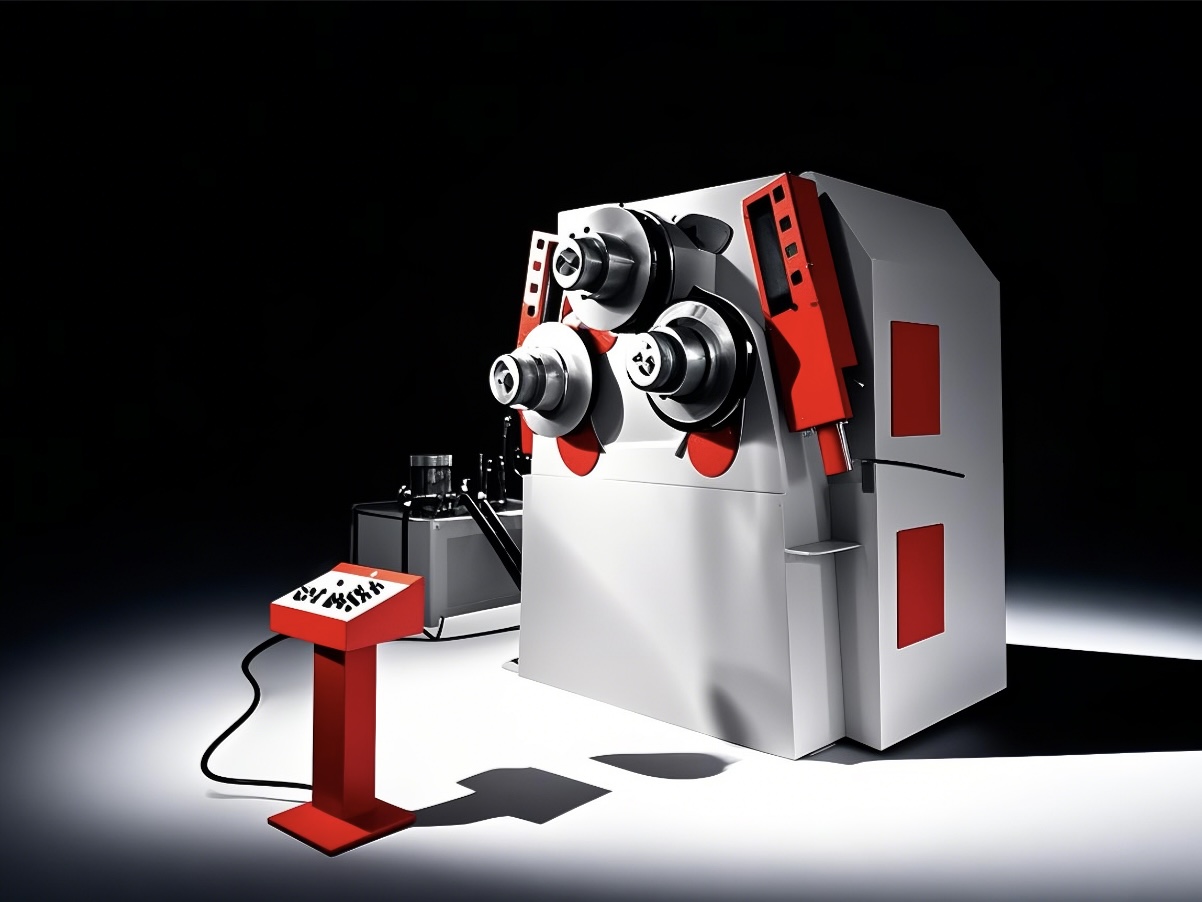

Hydraulic Profile Bending Machine

Heavy-Duty Double Profile Rolling Machine

Independently Adjustable, Double-End Pre-Bending Capability – Saving Profile, Low-Cost and Efficient

Hydraulic Heavy-Duty Double Profile Rolling Machine

With continuous operation capability, a simple structure, and low wear, the PBC Heavy-Duty Hydraulic Profile Bending Machine delivers strong bending performance and easy maintenance. It is ideal for industries requiring robust and accurate profile rolling, such as construction, shipbuilding, and heavy fabrication.

The PBC Double Pinch Profile Rolling Machine is designed for rolling of metal heavy-duty profiles, including beams, channels, tubes, angle bars, and other steel structures. It features a hydraulic motor drive, ensuring high torque output, superior precision, and extended durability.

Note: Double Pinch reduces flat ends, improves material utilization, and profile bending efficiency

Find Your Hydraulic Profile Bending Machine in 3 Steps

Double Pinch Design

Independently Adjust Both Bending Rollers Hydraulically—Virtually Eliminates Flat Ends

Two adjustable bottom bending rollers enable pre-bending at both ends, reducing material waste.

No need to remove and reposition the workpiece, save time in profile rolling.

Heavy-Duty Construction

The three bending rolls are main drive rolls, which can ensure the maximum torque required for rolling heavy-duty profiles.

Built with a robust steel frame for handling thick and large heavy-duty profiles.

High torque and strong bending force ensure smooth operation on tough materials.

Control System

CNC Opentional

Operator System with Windows.

Download .dxf files and quickly generate profile roll bending programs.

Handles complex curves, including spirals and ellipses.

Allows for programmable bending sequences.

Ensures repeatable accuracy with minimal operator intervention.

Control panel, Memory for 99 Programs of Bending Parameters

The PLC Records and Calls the Position of the Control Roller to Achieve the Production of Repeatable Workpieces.

Remote Control for Wireless Operation

3D Guide Rolls

3D Roll Bending Guide Rolls with three-dimensional adjustment. (X, Y, and Z Axis Three-dimensional Adjustment. )

Easy to Adjust.

Facilitate the Profile Rolling of Asymmetric Sections.

Roll Bending Angle Profile to ensure no cross-sectional deformation.

Spiral Bending (Z axis bending).

Support the Work Piece During Profile Bending.

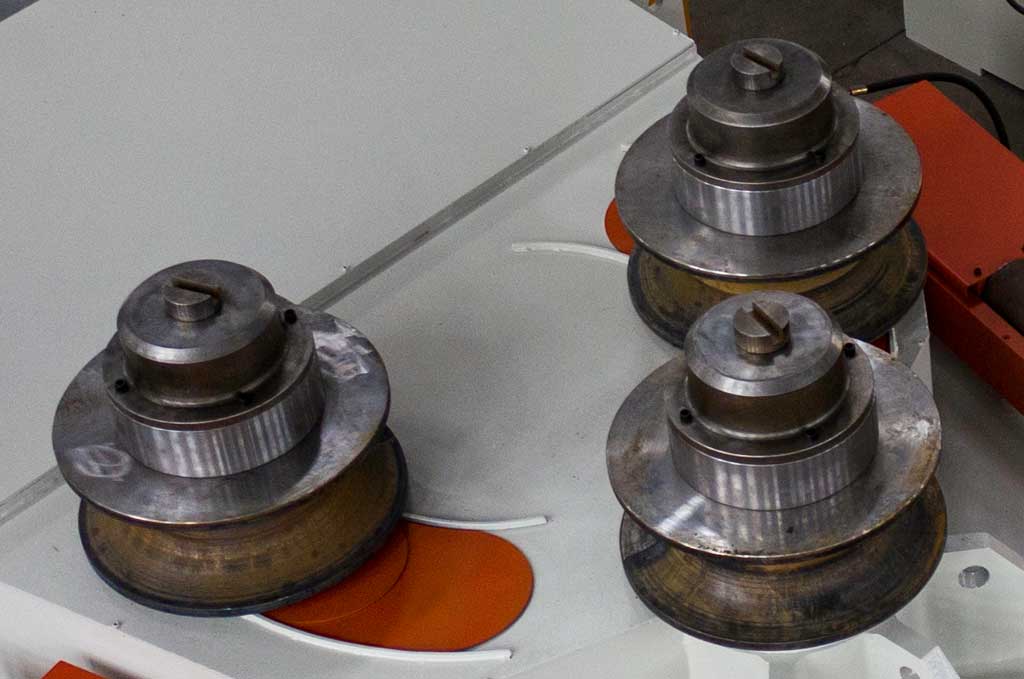

Combined Universal Roller/Mould

The combined universal roller is the standard configuration for the PBC hydraulic profile bending machine and is sold with the host.

Standard bending tools(rollers) of alloy steel, heat-treated to surface hardness 60 HRC.

Save Your Costs: The standard Combination Roll-Bending Combined Universal Roller can Rolling Most Profiles on the Market.

Flexible Placement

PBC Heavy-Duty Double Profile Rolling Machines offer the flexibility to be positioned both vertically and horizontally, accommodating different bending requirements. Working in a vertical position is recommended for smaller-diameter pieces, while larger diameters are better suited for horizontal positioning to prevent the weight of the piece from affecting the results.

Note: PBC machines can operate vertically for diameters <1500 mm or horizontally for larger ones to avoid weight distortion.