In modern metal forming technology, profile bending machines and rebar thread rolling machines are two highly representative types of equipment. One focuses on “shaping,” while the other emphasizes “thread forming.” Both play indispensable roles in construction, mechanical manufacturing, bridge components, and curtain wall engineering. Despite their different functions, they share the same metal plastic forming principle — by precisely controlling pressure and deformation, they achieve accurate and stable forming results.

Rebar Thread Rolling Machine — Strength and Precision Formed by Flat Thread Rolling Dies

A rebar thread rolling machine is a multifunctional cold rolling forming machine. It can perform thread, straight, and helical rolling on the surface of workpieces under cold conditions, as well as straightening, reducing, burnishing, and rolling of special-shaped parts. Equipped with an electro-hydraulic composite drive system, it allows manual, semi-automatic, and fully automatic operation modes, adaptable to different production rhythms and working conditions.

The core component of the thread rolling machine is the flat thread rolling die (also called the rolling plate). When a workpiece rolls between two or three relatively moving dies, the metal fibers are extruded and flow under high pressure, forming precise threads or patterns. This cold rolling process is a non-cutting forming method that effectively enhances surface finish and internal density. The compressive residual stress generated during rolling greatly improves the fatigue and torsional strength of the threaded part, making it a highly efficient, low-energy, and environmentally friendly process.

Common types of thread rolling machines include:

- Two-axis eccentric type, two-axis through-feed type, two-axis hydraulic type

- Three-axis cam type, three-axis hydraulic type, three-axis hydraulic through-feed type

Among them, the three-axis type is particularly suitable for hollow tubular parts, ensuring true roundness, concentricity, and perpendicularity. For different thread types, operators can simply replace the corresponding flat thread rolling dies to form triangular, trapezoidal, knurled, or helical threads.

Routine maintenance is equally important: check for air leakage and loose bolts before operation; lubricate regularly; clean the chips and disconnect the power supply after each operation. These seemingly small tasks determine the machine’s lifespan and reliability.

Profile Bending Machine

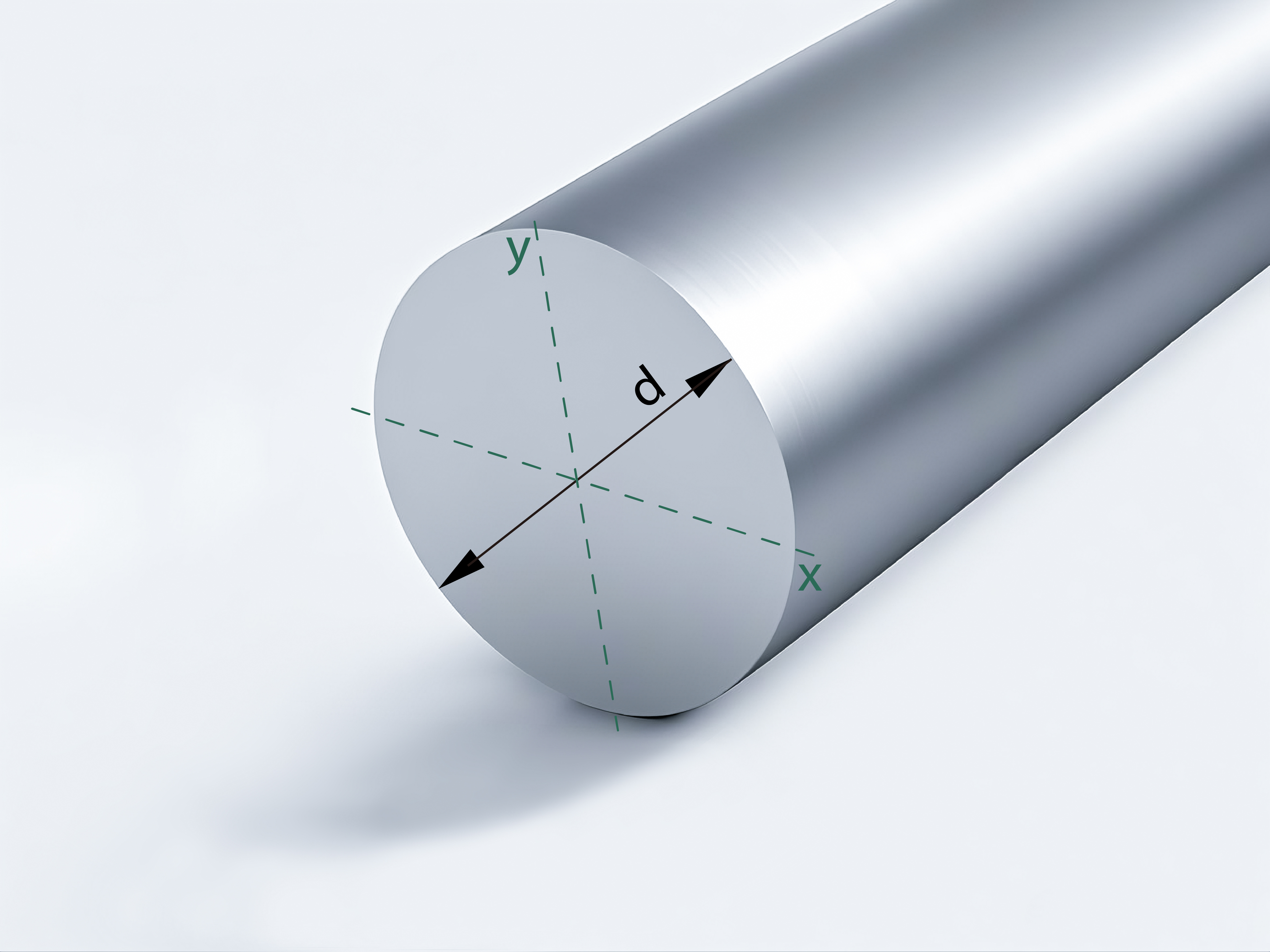

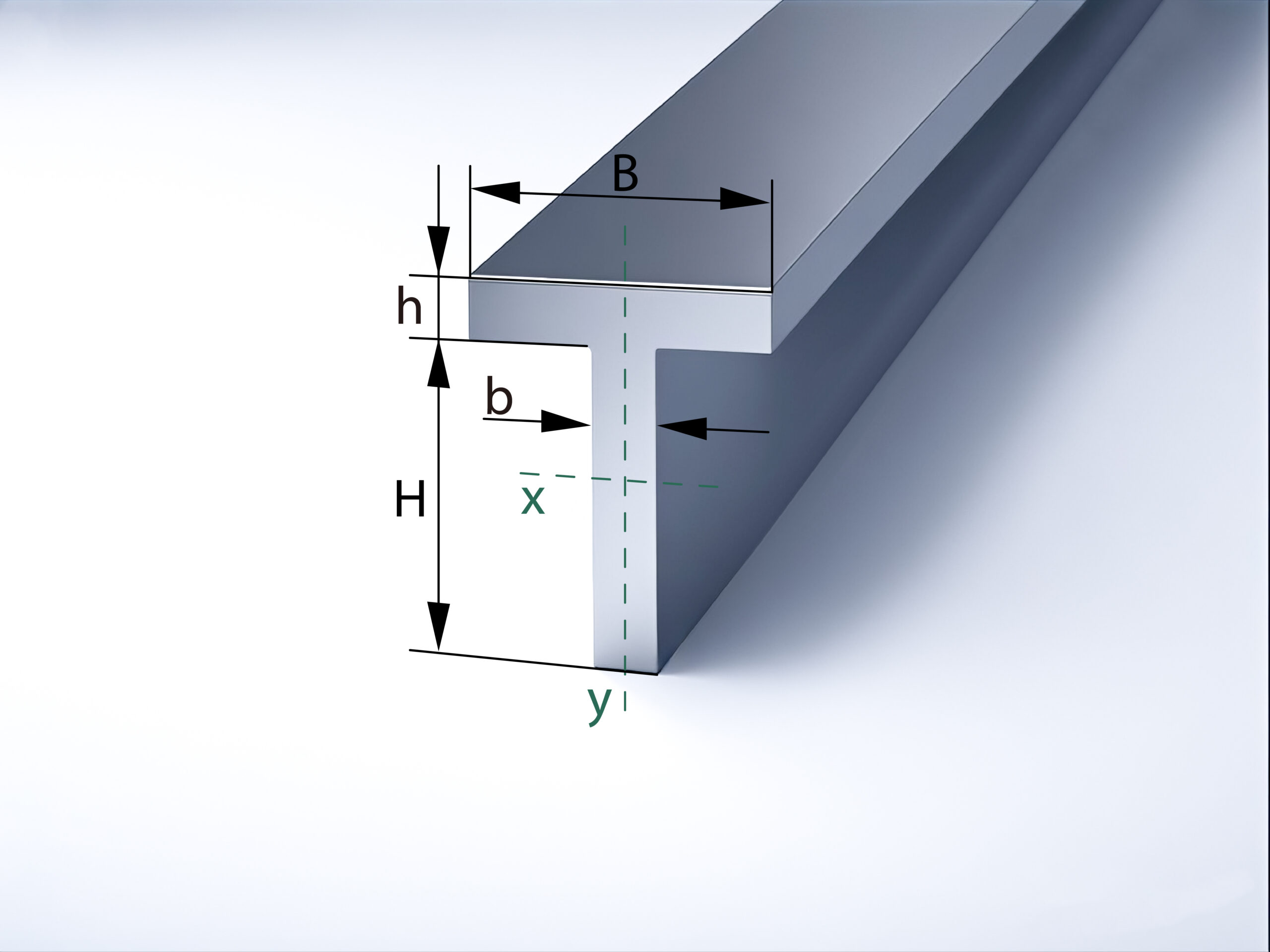

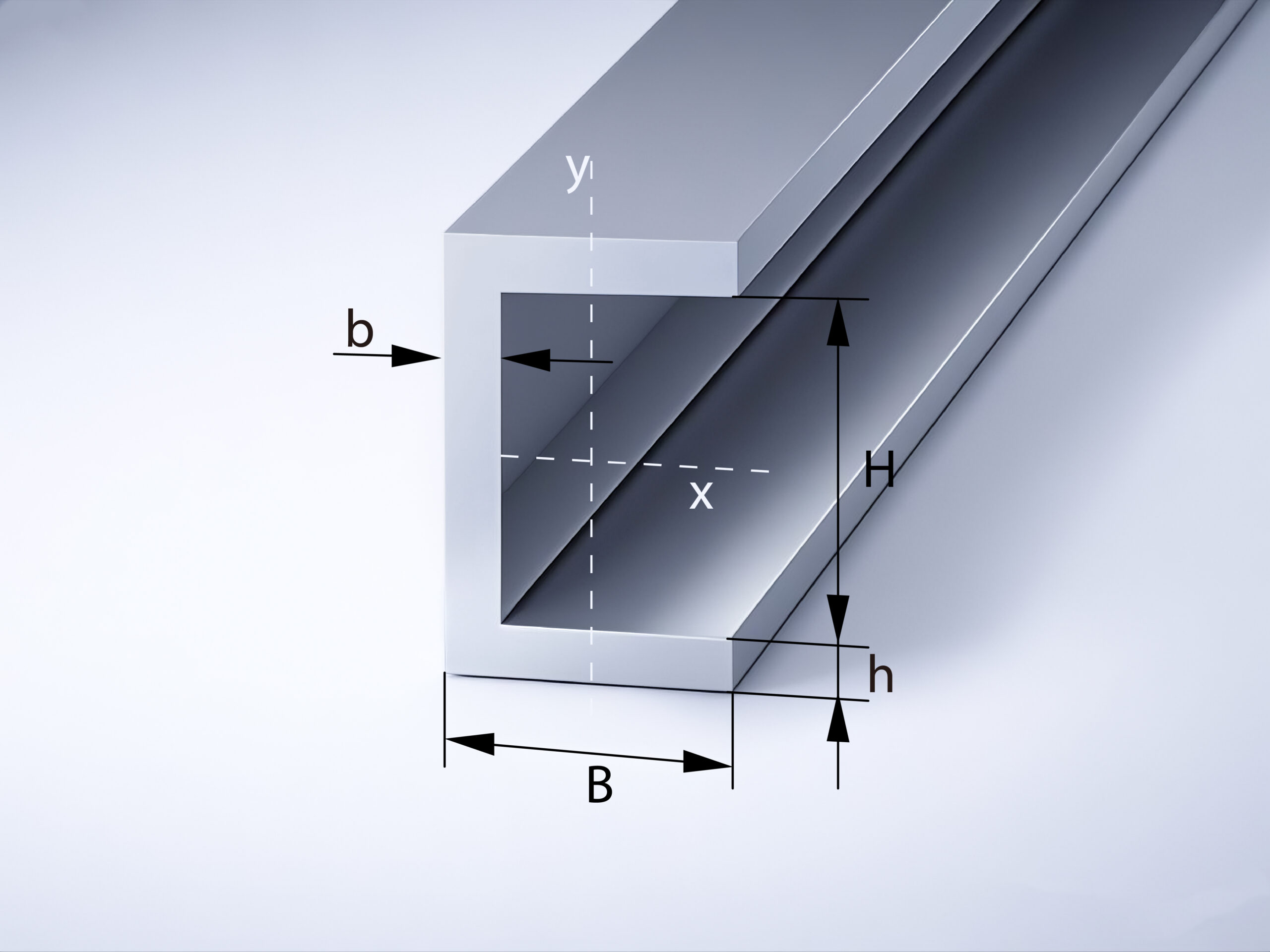

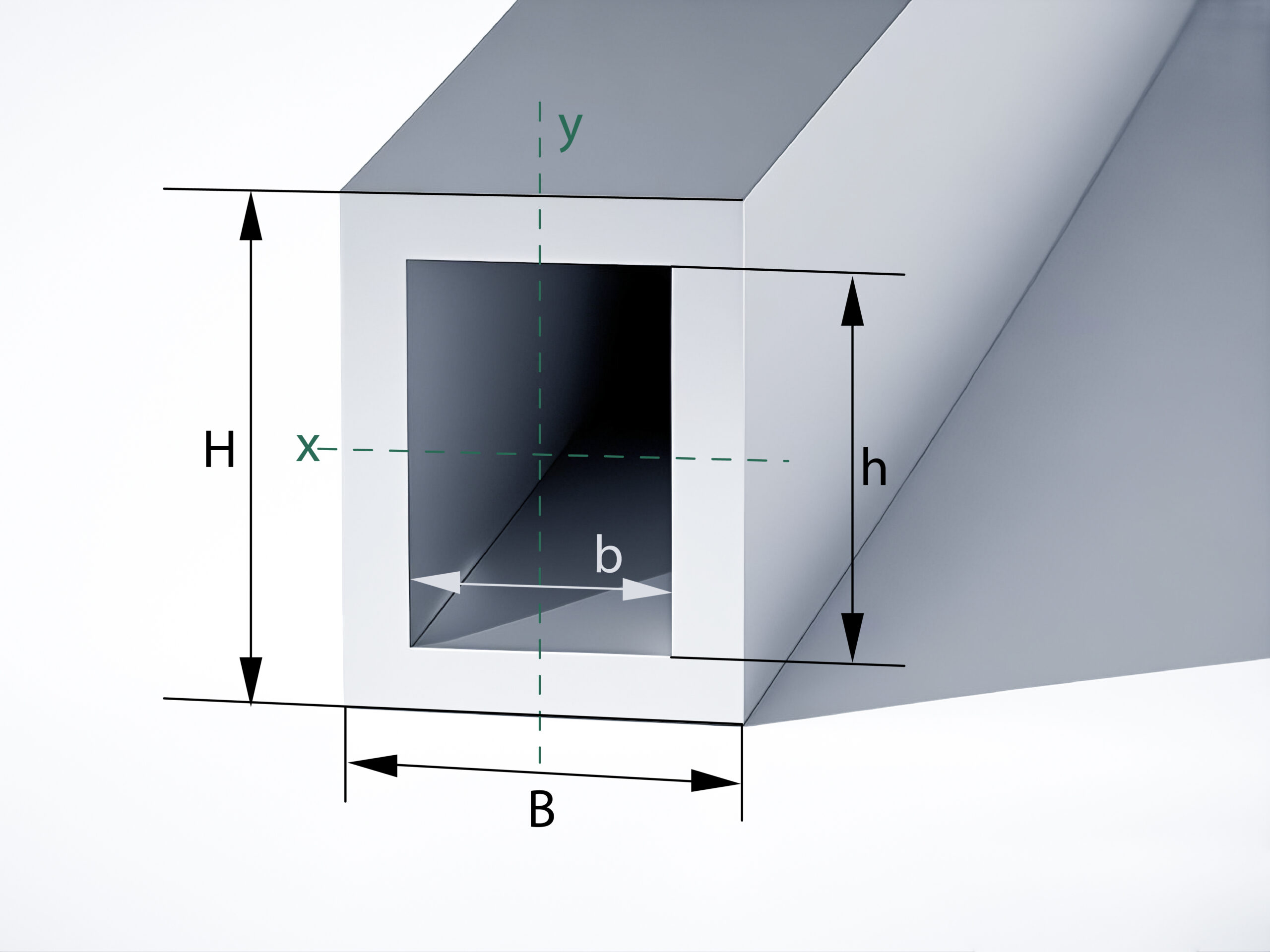

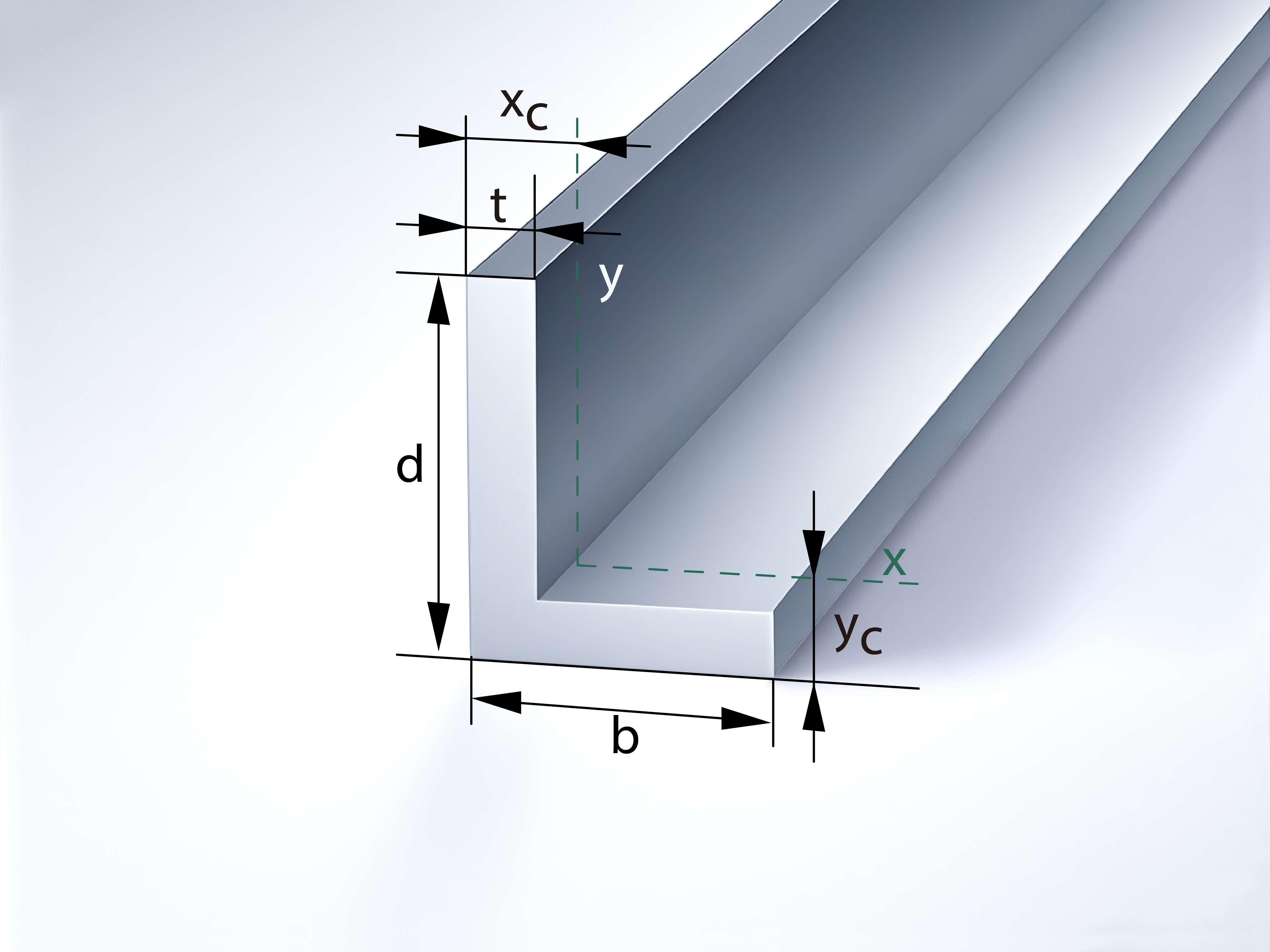

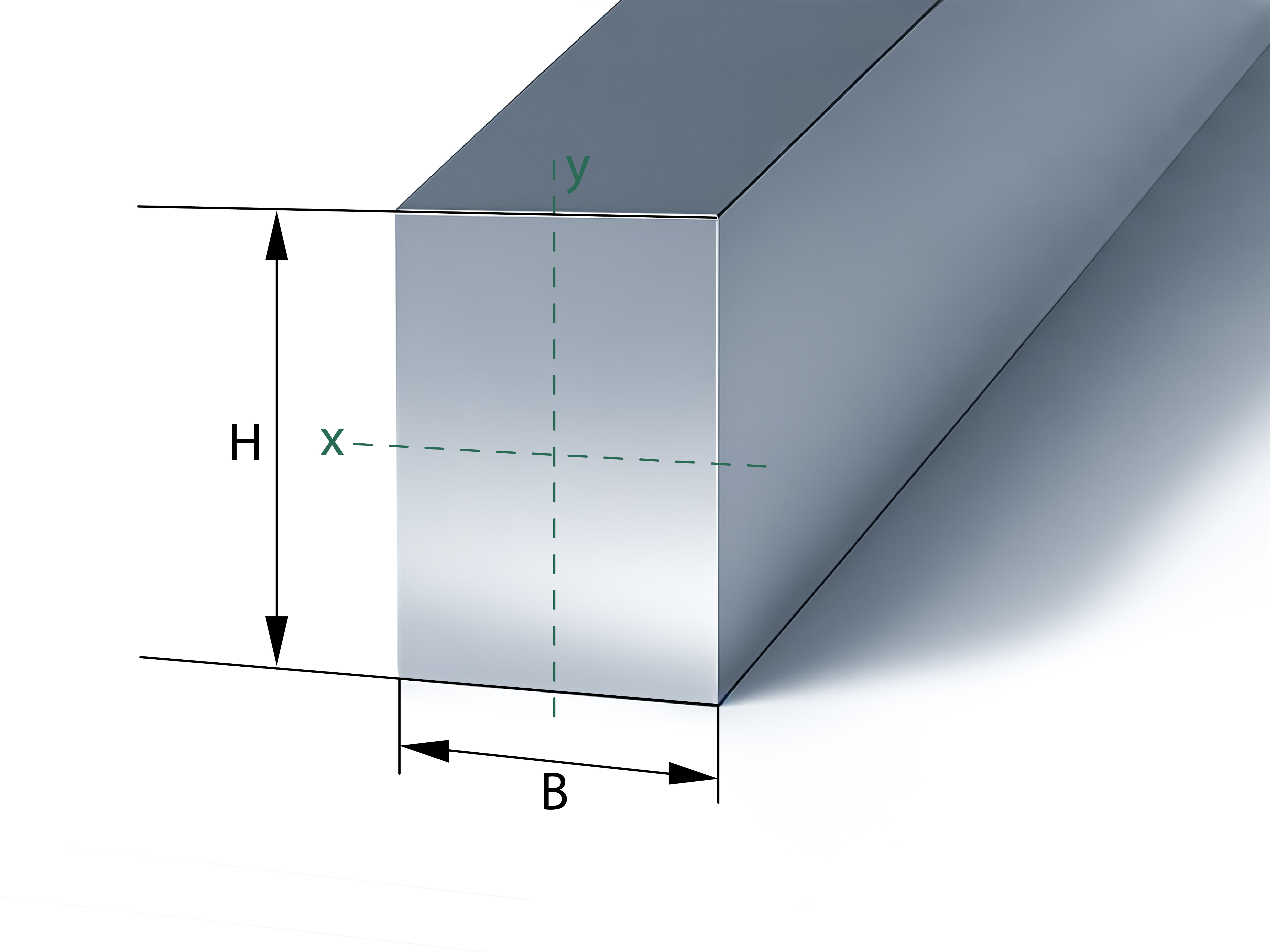

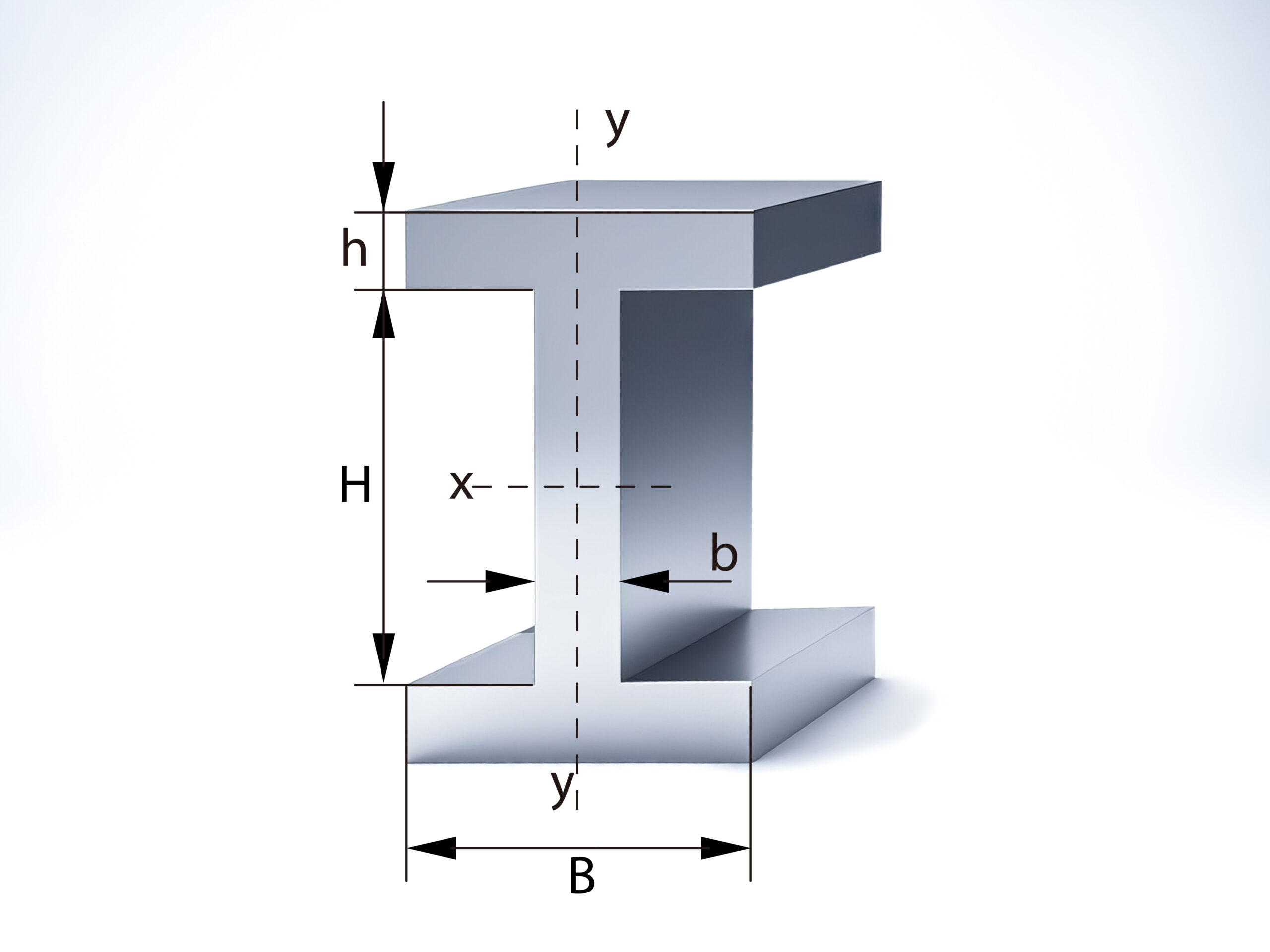

Unlike thread rolling machines, the profile bending machine is designed to change the shape of metal profiles. It can bend a wide range of materials such as aluminum profiles, flat bars, square bars, angle steel, H-beams, round pipes, square pipes, and rectangular tubes into required arcs or circular structures. It is an essential machine in curtain wall fabrication, automobile frames, and steel structure construction.

According to structural design, profile bending machines can be horizontal or vertical; according to roller adjustment method, they can be upper-adjusting or lower-adjusting.

Among these, the four-roller fully driven hydraulic type is the most advanced — powered by four independent hydraulic motors, it ensures fast rolling speed and high precision, completing pre-bending, circle forming, and calibration in a single feed.

The typical working principle is linear downward adjustment: the upper roller remains fixed, while the lower roller moves upward to clamp the workpiece. The two side rollers move vertically relative to the upper roller, controlled by the hydraulic system and monitored by a digital displacement display. For asymmetric profiles such as window or curtain wall sections, the machine is equipped with CNC support rollers and a torsion correction system to ensure smooth and accurate curves.

Differences, Common Ground, and Combined Applications

Although the rebar thread rolling machine and profile bending machine perform different functions, they share the same essence of metal plastic deformation. Both rely on rolling or bending within the yield limit of metal to redistribute its crystal structure, resulting in higher strength and improved surface integrity.

In many structural or fabrication workshops, these two machines often operate side by side:

- The profile bending machine forms the required curves for steel or aluminum beams;

- The thread rolling machine processes precise threads for the connection ends.

In some production lines, both processes are integrated — after bending, the ends of the profile are rolled with threads to achieve fast and accurate connections. This combined approach improves efficiency, assembly precision, and overall product aesthetics.

Whether it is the precise threads formed by flat thread rolling dies or the smooth arcs shaped by a profile bending machine, both form the foundation of modern manufacturing. The thread rolling machine makes “lines” stronger, while the bending machine makes “forms” more graceful. Together, they reflect the intelligence of mechanical engineering and the maturity and innovation of contemporary metal forming technology.